Need Industrial Air Filters or Cartridges? Choose the appropriate option for quick ordering. Now with Free Shipping!

Featured products

Search By Product, Application or Industry

We specialize in general plant air filtration, welding shop filtration systems, automatic and robotic welding cell filtration, and oil mist and particle control for any industry. Whether you challenge stems from welding fumes and smoke; laser and cutting fumes and smoke; grinding and deburring dust; dry dust; powders; machine processes; mist removal; sanding and finishing; vehicle exhaust or dust collection, we’ve got you covered.

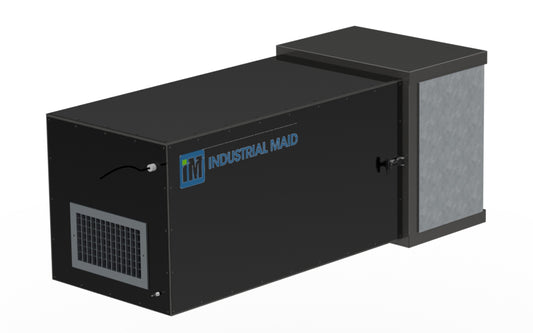

You're in a healthy place with Industrial Maid

Go Ahead, Breathe Easy, knowing you’re working with a company that started 15 years ago because we saw a better, more efficient, cost-effective and environment-friendly way to ensure your shop is clean, your employees are healthy, and your air quality is high. You’re at the best spot to find commercial and industrial air filtration solutions for your business with Industrial Maid.