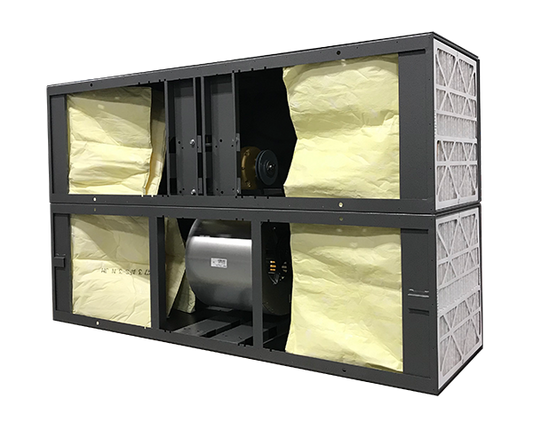

AZTech T-Series Industrial Air Cleaner Overview

Industrial Air Cleaners from Industrial Maid’s AzTech T-Series negate the need to exhaust expensive heated or cooled air outside. T-Series Industrial Air Cleaners pull contaminated air from the work area through a set of highly efficient air filters that remove harmful particles. The fresh air is then re-circulated back into the room. Additional money-saving features include standard size filters and lower horsepower ratings. Learn more about an Industrial air filtration system.

The specifications below provide an overview of features for the product series. Not all features are available for every product. Please contact us for more details or if you have any questions.

Learn more about how the AZTech T-Series Industrial Air Cleaners help with fume extraction, welding smoke collection, industrial dust extraction, oil mist filtration, and the capture of most airborne nuisance dust, mist, and vapors. You can also check out our article on How to Choose an Industrial Air Cleaner System for your shop.

- Ductless and modular space-saving design

- Light-weight

- Quiet operation

- Disposable filters for easy, uncomplicated maintenance

- Effective for a wide range of use including oily welding applications

- Low installation, energy, and maintenance cost

- Available in polyethylene plastic or powder-coated carbon steel with a 16-gauge steel frame

- Four-inch Merv 7 pleated industrial pre-filters to catch the larger particles, which extends the 2nd stage Merv 15 multi-pocket bag filter’s life

- Easily relocated to accommodate growth or space redesign

- Additional options include: spark baffles, carbon panels, carbon V-banks, and HEPA after-filter

AZTech T-Series Industrial Air Cleaner Product Insights

Additional industrial air cleaner options include filter saver pads, spark baffles, and a variety of other filter media designed to match the size of dust particles or help better control wet oily smoke and oil mist. Industrial Maid designed the T Series in a modular configuration, allowing for air cleaners to be built in a number of vertical, horizontal, or even quad configurations to fit your specific application and budget.

Check out the specs, add to your cart, or contact us about what air cleaner is right for your needs.

-

T-4500 - Industrial Air Cleaner 4500 CFM

Regular price $0.00Regular priceUnit price per -

T-6000 2 Module Industrial Air Cleaner 6000 CFM

Regular price $0.00Regular priceUnit price per -

T-7500 4 module Industrial Air Cleaner 7500 CFM

Regular price $0.00Regular priceUnit price per

Industrial Dust Collectors

Determine your CFM Need by Application

Application Guidelines

Some of the most popular applications for the self-contained AZTech units are welding fume ventilation, grinding dust, diesel smoke, oil mist, granite dust and composite dust. Optional HEPA and charcoal filters are available for more demanding industrial ventilation system applications.

| Applications | Air Exchange Rates (Minutes) |

|---|---|

| Welding | 4-6 |

| Grinding | 6 |

| Plasma cutting collection over a wet table | 6-8 |

| Diesel Smoke | 8 |

| Foundry | 6-8 |

| Wood Working | 8-10 |

| General Ambient Air | 10 |

Contact the staff at Industrial Maid for additional applications not listed above. Call: 402-798-7116

Step 1

Determine the AER – Air Exchange Rate from Table 1 that best fits your application needs.

Step 2

Determine the total cubic feet of your plant work area

Total cubic feet = L x W x H (maximum height 20’)

Where:

L = length of your workspace (feet)

W = width of your workspace (feet)

H = height of your ceiling in the workspace (feet)

Note – we use dimensions only to 20 feet as smoke, dust and fumes will stratify well below this height. Example: 24 ft ceiling height—20 ft.

Step 3

Divide the total cubic feet by the AER determined in Step 1.

Step 4

Divide this total by the CFM of the unit you prefer to use.

T-3000 is 3000 CFM

T-3500 is 3500 CFM

T-4500 is 4500 CFM

T-6000 is 6000 CFM

T-7500 is 7500 CFM

Example:

Workspace is 100’ long X 60’ wide X 18’ tall

Total cubic feet is: 100 X 60 X 18 = 108,000 cubic feet

Welding application

Medium use 5 as the AER (air exchange rate)

(from Table 1) 108,000/ 5 = 21,600

Assume using a T-3500 (3500 CFM unit)

21,600/3500 = 6.17 or 6 units to handle the application.

Step 5

Determine best location or placement for units.

Our qualified staff is always available to help you determine CFM requirement, placement and then final selection of the units that will provide you the best “cost of ownership” in regards to electrical consumption and filter service costs. Contact Sales @ (877) 624-3247

*Source capture may be required to meet OSHA, PEL or TWA requirements. General guidelines only, consult factory for specific details.