Commercial Air Filtration Overview

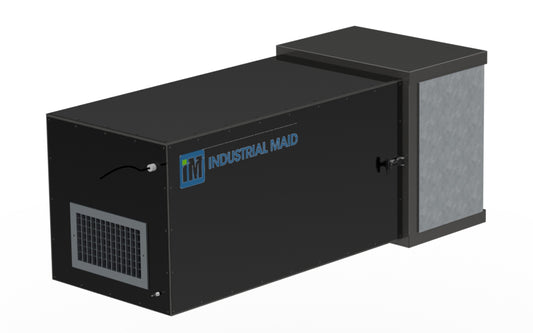

The commercial air cleaner / commercial air filtration system is designed for collecting dust, smoke, fumes, and other nuisance dust from lighter loading applications. This solution is ideal for schools, bakeries, print shops, IT centers, wood shops and others. It recirculates air to collect harmful particulate, smoke and vapors that have become airborne in the workspace.

The below specifications overview features available on the product series, not all features are available on each product. Please contact us for more details or questions.

- Energy Efficient

- Two and three-stage filtration

- Standard 3/16” black matte recycled polyethylene plastic panel

- Easy change-out filters

- 115 Volt with 12ft power cord

- High/low/off switch

Commercial Air Filtration Product Insight

Additional model options include a silencer, eyebolts, manometer and MERV 11 bag filters.

Check out the specs, add to your cart or contact us about what air cleaner is right for your needs.

-

T3000S-MM Air Filtration Unit

SKU: AIR-A007

Regular price $2,499.99Regular priceUnit price per -

2500 Commercial Air Cleaner 2500 CFM

SKU: 2500-STOCK

Regular price $3,581.00Regular priceUnit price per -

2000C - Commercial Air Cleaner 2000 CFM

SKU: 2000C-STOCK

Regular price $2,580.00Regular priceUnit price per -

T-3000 Commercial Ambient Air Cleaner 3000 CFM

SKU: T3000-STOCK

Regular price $3,011.00Regular priceUnit price per

Available Commercial Air Cleaners Downloads:

Snapshots & Details

Application Guidelines

Some of the most popular applications for the self-contained commercial air cleaners are 3D printing, art studios, bakeries, print shops, wood working and many more. Different filter configurations can be placed in these units to suit almost any application.

| Applications | Air Exchange Rates (Minutes) |

|---|---|

| Art Studio | 6-8 |

| 3D Printing | 8 |

| Bakery (Flour) | 8-10 |

| Print Shops | 8-10 |

| Wood Working | 8-10 |

| Maker Spaces | 8-10 |

| IT/Computer Centers | 10 |

| General Ambient Air | 10 |

Contact the staff at Industrial Maid for additional applications not listed above. Call: 402-798-7116

Step 1

Determine the AER – Air Exchange Rate from Table 1 that best fits your application needs.

Step 2

Determine the total cubic feet of your plant work area

Total cubic feet = L x W x H (maximum height 20’)

Where:

L= length of your workspace (feet)

W= width of your workspace (feet)

H= height of your ceiling in the workspace (feet)

Note – we use dimensions only to 20 feet as smoke, dust and fumes will stratify well below this height. Example: 24 ft ceiling height—20 ft.

Step 3

Divide the total cubic feet by the AER determined in Step 1.

Step 4

Divide this total by the CFM of the unit you prefer to use.

2000c is 2000 CFM

2500 is 2500 CFM

T-3000 is 3000 CFM

Example:

Workspace is 40’ long X 40’ wide X 12’ tall

Total cubic feet is: 40 X 40 X 12 = 19,200 cubic feet

3D Printing application

Use 8 as the AER (air exchange rate)

(from Table 1) 19,200/8 = 2,400

Assume using a Model 2,500 (2,500 CFM unit)

2,400/2,500 = .96 or 1 unit(s) to handle the application.

Step 5

Determine best location or placement for units.

Our qualified staff is always available to help you determine CFM requirement, placement and then final selection of the units that will provide you the best “cost of ownership” in regards to electrical consumption and filter service costs. Contact Sales @ (402)798-7116

*Source capture may be required to meet OSHA, PEL or TWA requirements. General guidelines only, consult factory for specific details.

We take Industrial Air Filtration to the Next Level with Full Line Designs

Our experience and commitment to commercial air purification has brought us to where we are today – manufacturing complete air filtration systems & industrial ventilation products that provide the best performance, efficiency and capacity for the money.

At Industrial Maid we strive to be a full line provider of all your industrial air filtration needs. When comparing air filtration systems, we guarantee that Industrial Maid equipment gives you the best dollar value in the industry. All of our industrial ventilation units are manufactured at our plant in Cortland Nebraska and our customers trust that every product we sell is of the highest quality in both design and construction. Listening to our customers has made our engineering team keenly aware of how important it is to maximize return on investment. You will find that all Industrial Maid air cleaners are designed with close attention to achieving low maintenance costs and extended service intervals without compromising airflow and efficiency.