Auto Body Shop

Auto body shops generate a diverse range of air particulates, including paint particles containing volatile organic compounds (VOCs) and heavy metals, metallic particles from grinding and welding activities, dust from sanding residues, solvent vapors from cleaning and paint thinning, carbon monoxide, volatile organic compounds (VOCs), and exhaust emissions from vehicles. These airborne contaminants pose significant health and environmental hazards, necessitating effective air filtration solutions within auto body shop environments. Implementing advanced air filtration systems is crucial for mitigating these risks and ensuring compliance with air quality regulations. Proper ventilation systems, coupled with high-quality air filters, help capture and remove harmful particulates, safeguarding both workers' health and the surrounding environment. Regular maintenance and inspection of filtration equipment are essential for optimal performance and sustained air quality improvement in auto body shops.

Auto Body Air Quality Concerns

Auto body shops can produce various types of air particulates, which can pose health and environmental risks if not properly managed. Some common types of air particulates generated in auto body shops include:

- Paint Particles: Fine particles generated during painting activities, including spray painting, can contain volatile organic compounds (VOCs), heavy metals (such as lead, chromium, and cadmium), and other hazardous substances present in paints and coatings.

- Metallic Particles: Grinding, sanding, cutting, and welding activities in auto body shops can produce metallic particulates from materials such as steel, aluminum, and other metals present in vehicle parts and components.

- Dust and Sanding Residues: Sanding of surfaces, body filler application, and other surface preparation activities can generate dust and particulates composed of various materials, including fiberglass, plastic, and other composite materials used in vehicle construction.

- Solvent Vapors: Use of solvents for cleaning, degreasing, and paint thinning purposes can result in the release of solvent vapors, which can contribute to air pollution and pose health risks.

- Carbon Monoxide and Volatile Organic Compounds (VOCs): Combustion processes from equipment such as spray booths, ovens, and other heating systems can emit carbon monoxide (CO) and VOCs, which are air pollutants and can have adverse health effects.

- Exhaust Emissions: Running vehicles within or near auto body shops can lead to the infiltration of exhaust emissions, including particulate matter, nitrogen oxides (NOx), carbon monoxide (CO), and other pollutants, especially if the shop lacks proper ventilation.

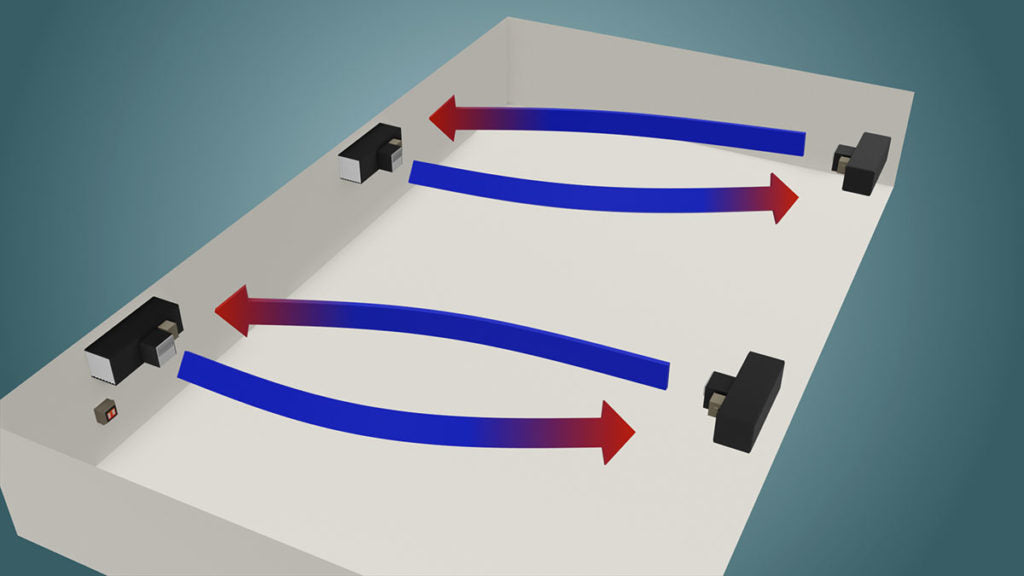

To mitigate the risks associated with these air particulates, auto body shops should implement effective ventilation systems, use proper personal protective equipment (PPE), adhere to regulations regarding the handling and disposal of hazardous materials, and employ best practices for waste management and pollution prevention. Regular maintenance and inspection of equipment and facilities are also essential to ensure optimal performance and minimize air pollution.

Safer Environment. Safer Employees.

Search By Product, Application or Industry

We specialize in general plant air filtration, welding shop filtration systems, automatic and robotic welding cell filtration, and oil mist and particle control for any industry. Whether you challenge stems from welding fumes and smoke; laser and cutting fumes and smoke; grinding and deburring dust; dry dust; powders; machine processes; mist removal; sanding and finishing; vehicle exhaust or dust collection ? We’ve got you covered.