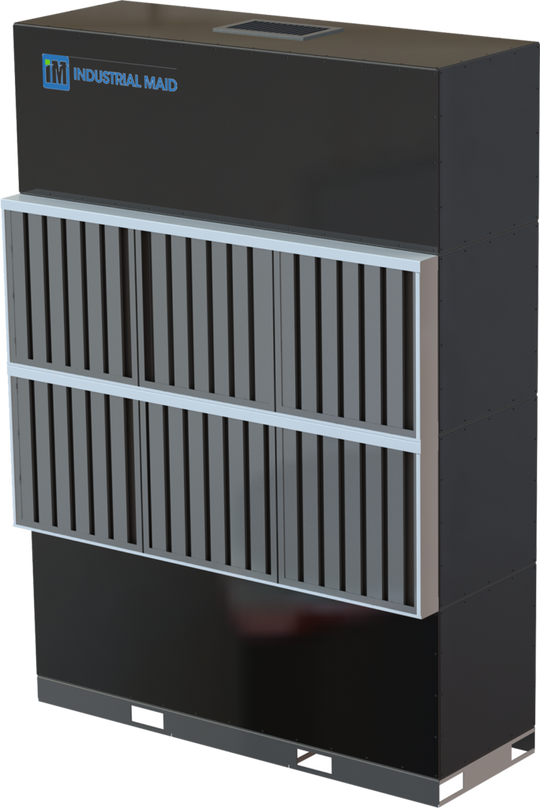

Filter Wall Overview

Industrial Maid is a leader in the industrial media air filtration industry, providing practical, modular “side and back-draft” style industrial filter walls. The multi-stage filtration design of our U.S.-made industrial air cleaners give the flexibility to properly select the right media to collect grinding and finishing dust, welding smoke or fumes.

The below specifications overview features available on the product series, not all features are available on each product. Please contact us for more details or questions.

- Arrives ready for placement and wiring to electrical power

- Low-energy and low-cost system

- Custom from 53” tall to 114” tall

- CFM ranges from 3,000 to 7,500

- No compressed air

- Easy to handle dump trays (EB34 and EB56 models only)

- Simple and safe

Filter Walls Product Insight

Additional model options include a silencer, manometer, dust drawers, HEPA final filter, magnahelic pressure gauge and MERV 11 bag filters.

Check out the specs, add to your cart or contact us about what air cleaner is right for your needs.

-

FW35 Filter Wall 3500 CFM

Regular price $0.00Regular priceUnit price per -

FW60 - Filter Wall 6000 CFM

Regular price $0.00Regular priceUnit price per