Controlling Nuisance Dust

Exposure to nuisance dust can happen through a variety of tasks at a machine, manufacturing or agricultural plant as well as other industries. Nuisance Dust is created from cutting, grinding, machining, polishing, sanding and other activities used to form or finish metal and other materials. It’s important for you to identify the exposure your workforce has to these dusts and keep levels small to none—or at a minimum, an acceptable level as dictated by OSHA standards around nuisance dust.

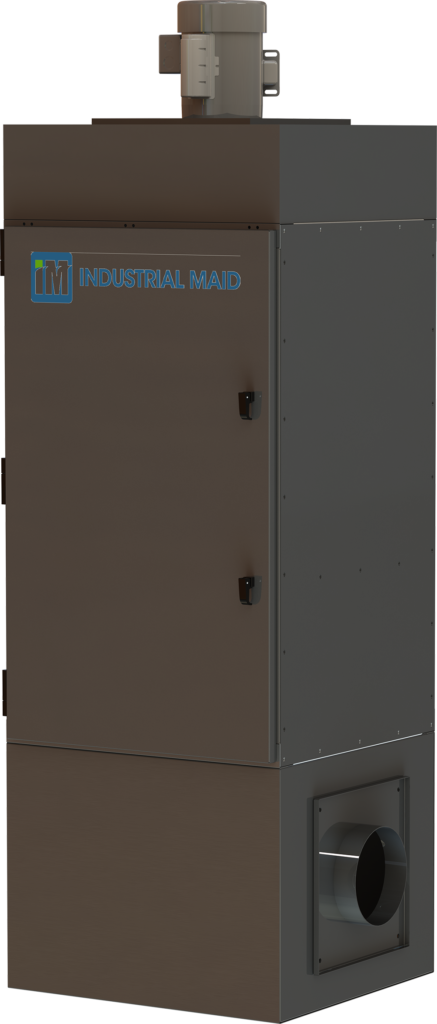

This can be achieved by providing proper ventilation that reduces concentration levels, providing respiratory protection when necessary, and following basic housekeeping rules—all things that Industrial Maid has been providing industries for years.

What is Nuisance Dust?

Nuisance dust is a term used for airborne materials that don’t typically produce significant harmful effects if exposed to them over a period of time. But, in large amounts can cause irritation by reducing visibility, creating layers of dust and dirt that could affect machine operation or cleanliness—and getting into the eyes, ears, nose or mouth. Nuisance dust can also cause irritability when removed, depending on the amount and sensitivity of the skin.

OSHA does have regulations and limits on the amount of chemical or substance workers can be exposed to, but nuisance dust is a general term relating to a combination of chemicals so the specific limits of “nuisance dust” grouping doesn’t exist.

That being said, don’t let the term nuisance dust let you think that these dusts are harmless. Research on these dusts is ongoing and while there isn’t known to be as much risk with nuisance dusts, exposure to any dust can cause respiratory issues and can lead to other more serious side effects.

If you’re concerned about nuisance dust or looking for a solution to eliminate and minimize it in your shop, give us a call, we’ve got just the right solution.